Shandong Danflex Hose Co., Ltd. is one of the leading manufacturers and suppliers of ptfe hose in China, also supporting customized service. Be free to buy cheap ptfe hose for sale here and get quotation from our factory. Good service and reasonable price are available.

Why choose us

Production Equipment

Our company has first-class production equipment, including advanced automated production lines, precision cutting and assembly equipment, as well as high-performance pressure testing instruments. All production equipment is regularly maintained and calibrated in accordance with international standards to ensure that each batch of hose produced meets the strict quality requirements.

Our Product

The company mainly produces Sewer Jetting Hose,Ultra High Pressure Thermoplastic Hose,SAE 100 R7 Hose,SAE 100 R8 Thermoplastic Hose,Water Jetting Hose,High Pressure Paint Spray Hose,UHP Series Ultra High Pressure Flexible Hose,High Pressure Sewer Jetting Hose,Waterblasting Lance Hose,Hydraulic Jack Hose,Micro Test Hose,Lubrication Grease Hose,CNG Hose,PTFE braided Hose,SAE100 R14 Hose,etc.

Product Application

Our products are widely used in water jet, hydraulic, oil, gas and automotive industries. From high pressure cleaning to industrial spraying to precision mechanical lubrication, DANFLEX hoses provide efficient and safe fluid transfer solutions for a wide range of industries thanks to their excellent pressure resistance, wear resistance and flexibility.

Production Market

We have high efficiency sales team and competitive price superiority, and attract customers from all over the world, we export to many countries, including Russia, USA,Europe, Mexico, Brazil, India,Singapore,Malaysia, Thailand ,Spain,Chile,Middle east and South Africa. It has been well received by customers at home and abroad.

PTFE hose is used in a variety of applications. This type of industrial hose uses an interior of PTFE, also commonly known by its brand name Teflon. You are likely already familiar with PTFE, as it's what most non-stick pans are coated with.

SAE 100 R14 Hose is a high performance hydraulic hose designed for use in demanding hydraulic systems.

With excellent corrosion resistance, this hose is resistant to most chemicals and is stable in a variety of harsh chemical environments.

PTFE Hose is a high performance hose made of high quality polytetrafluoroethylene (PTFE) resin.

Our PTFE Teflon Hose represents the perfect combination of advanced technology and high performance.

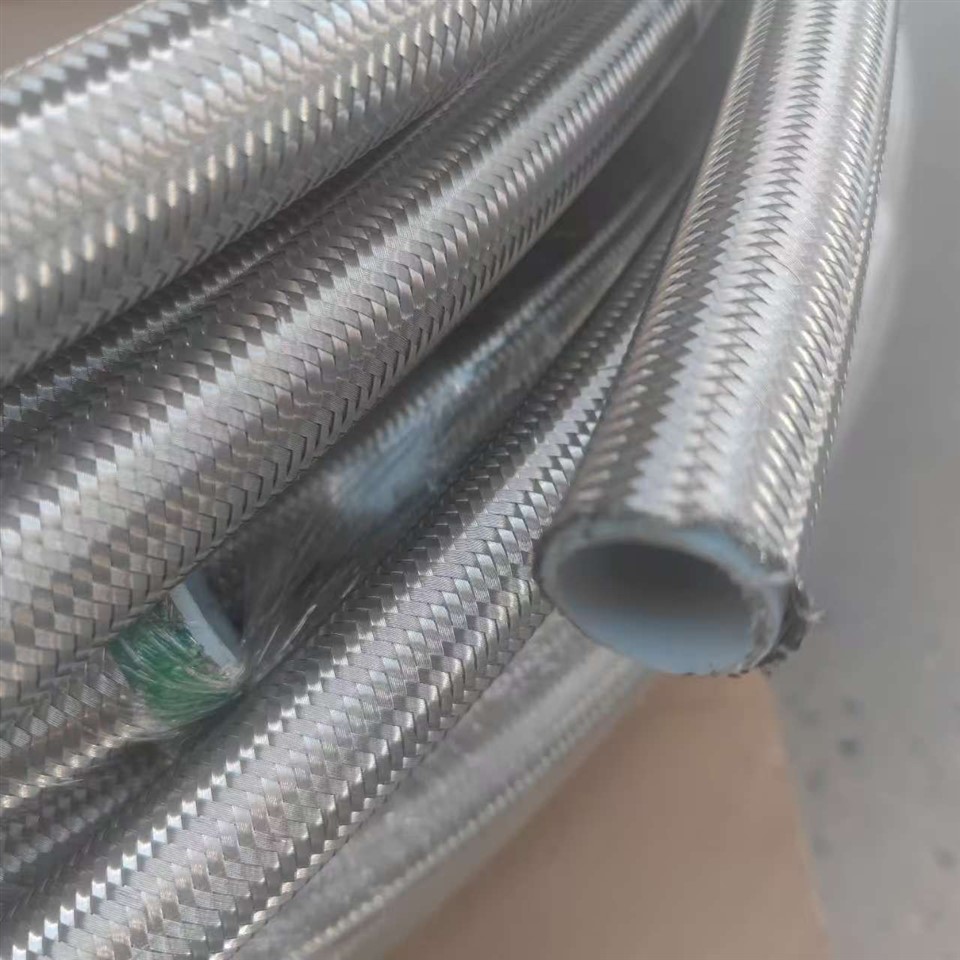

PTFE Braided Hose is a kind of high performance pipe product, its inner layer is made of PTFE material, and the outer layer is woven with stainless steel 304. This unique structure gives it excellent performance.

High Chemical Resistance

Teflon hoses are highly resistant to many compounds, including acids, alkalis, solvents and corrosives. This allows the use of PTFE hoses for conveying aggressive materials.

Heat Resistance

PTFE hoses can withstand extreme temperatures, both high and low. They have excellent thermal stability, which allows them to maintain their physical properties and performance even in harsh environments.

Non-adhesion

PTFE is a non-stick material, which means it has a very low coefficient of friction. This property makes Teflon hoses ideal for applications where sticky materials are transported, such as in the food processing industry. Another advantage of non-stick is that the hose is easy to clean.

Flexibility

PTFE hoses provide excellent flexibility and are easily bent, making them easy to fit and place in complex configurations. This flexibility allows for easier installation, reduces the need for additional adapters, and allows them to be used in tight spaces or hard-to-reach applications.

Electrical Insulation

It is also an important aspect that PTFE is an electrical insulating material, which contributes to the fact that Teflon hoses can be used in areas where electrical insulation is required. It is often used in the electronics and electrical industries, especially for the transfer of high purity chemicals and gases.

Low Friction

PTFE hoses have a smooth inner surface, thereby resulting in minimal friction during fluid flow. This feature enables efficient and undisturbed flow, reducing pressure drop and optimizing system performance.

Long Life And Durability

Hoses of this type have a long service life due to their resistance to chemical degradation, high temperature stability and excellent mechanical properties. They withstand repeated use, harsh conditions and exposure to various elements without significant wear or deterioration.

Composition and Structure

PTFE hose is composed of a smooth bore inner core made of PTFE material. This core is typically reinforced with braided stainless steel wire or other suitable materials to enhance the hose's strength and pressure resistance.

The outer cover can be made of stainless steel, polypropylene, or other protective materials depending on the specific application requirements.

The structure of a PTFE hose consists of several key components that work together to provide its unique properties.

Inner Core: The inner core of the PTFE hose is made of Polytetrafluoroethylene (PTFE) material. PTFE is a fluoropolymer known for its exceptional chemical resistance and low friction characteristics. The inner core is smooth and provides a non-stick surface for fluid transfer.

Reinforcement: To enhance the strength and pressure resistance of the hose, it is reinforced with braided stainless steel wire or other suitable materials. The reinforcement layer adds structural integrity and prevents the hose from collapsing or bursting under high-pressure conditions.

Outer Cover: The outer cover of the PTFE hose is designed to protect the inner core and reinforcement. It can be made of stainless steel, polypropylene, or other protective materials depending on the specific application requirements. The outer cover also provides additional resistance against abrasion, chemicals, and external factors.

What are Features of PTFE HOSES

Excellent Chemical Resistance

PTFE is renowned as the most chemically resistant material known. Only a very few, very unusual substances and conditions can affect it, like Fluorine gas at high temperature and pressure and liquid, boiling sodium metal.

PTFE lined hoses can therefore be used for a wider variety of chemicals than any other hose type, making it the ideal choice for very corrosive chemical applications and multiproduct applications.

Non-Stick Surface

The use of PTFE as a surface for cookware products has demonstrated to the world how easily cleanable PTFE surfaces are.

This means that PTFE lined hoses can be purged 100% clean more easily, faster and more reliably than any other type of hose.

Excellent Temperature Range

Temperatures from -70ºC up to +260ºC, dependent upon the hose design and the application conditions.

Hose Maintenance Tips

Prevent premature washdown hose wear and failure. Washdown hoses are often subjected to physical abuse while in service. Select a hose that meets or exceeds the application it is intended for.

Consider temperature, pressure, and environmental concerns such as abrasion and chemical resistance. Every plant should have a maintenance and inspection plan in place to ensure the longest possible life of the hose.

Be sure to consider these steps in your plan:

Store hoses properly when not in use. Hose racks or reels are highly recommended to keep hoses off the floor and out of harm's way. Pay attention to humidity, temperature, ozone, and sunlight. Storing them out of direct sunlight, in a room with moderate humidity and a temperature range of 50° to 75°F, is recommended.

Always shut off the water supply to the hose when not in use, and open the nozzle to relieve the pressure before storing. Leaving water in the hose subjects it to constant pressure and will shorten its life.

Don't pull the hose by the nozzle; this puts undue stress on the connection point.

Avoid exceeding the hose's rated bend radius. Kinking the hose can create weak spots in the hose wall. Consider using hoses with internal springs or kink guards to prevent kinking directly behind the coupler.

Never exceed the rated temperature and working pressure of a hose assembly.

Routinely inspect hoses for wear and damage. Look for external damage such as stiffness, discoloration, cuts, cracks, kinks, blisters, excessive abrasion, and exposed or broken wires.

Regularly inspect fittings. A hose should be removed from service if any fitting movement or damage is found that could prevent it from operating as intended.

Applications of PTFE Hose

PTFE hose finds applications in various industries due to its unique properties. Some common applications include:

Chemical Industry

In the chemical industry, PTFE hose is used for transferring aggressive chemicals, acids, and solvents safely. Its exceptional chemical resistance ensures the integrity of the conveyed fluids and prevents contamination.

Automotive Sector

PTFE hose is widely used in the automotive sector for fuel lines, power steering systems, brake systems, and other fluid transfer applications. Its resistance to chemicals, high temperatures, and pressure make it suitable for demanding automotive environments.

Pharmaceutical and Biotech Industries

In pharmaceutical and biotech industries, PTFE hose is utilized for transferring sensitive fluids, including pharmaceutical ingredients and biotech products. Its smooth inner bore prevents particle entrapment and ensures hygienic and contamination-free transfer.

Food and Beverage Industry

PTFE hose is employed in the food and beverage industry for handling food-grade liquids, beverages, and dairy products. Its non-reactive nature and high-temperature resistance make it a safe choice for maintaining the quality and purity of consumables.

Things to Consider When Choosing a PTFE Hose for Your Application

At first glance, hoses may seem simple and are often overlooked, not regarded as focal points amid other engineered components in an application. This neglect may contribute to hoses being subjected to abuse and mistreatment in the field. However, hoses represent a complex network of elements that work together to perform tasks typically handled by piping or tubing. Their essential function as a "flexible connection" on a P&ID is easily taken for granted. To select the proper hose for an application, one must consider material compatibility, hose strength, flexibility, insulation, and permeation, among other factors. Misunderstanding any of these aspects during specification can dramatically impact the hose's service life, leading to increased maintenance and heightened safety risks.

Materials

Most hoses fall into one of five families: Metal, Hybrid, Fluoropolymer, Thermoplastic, and Rubber. Each type has its limitations, so where should you start? A quick way to narrow down the options for a specific application is to compare the design pressure and temperature against different hose types.

Metal Hose: Made from a thin corrugated tube, metal hoses offer flexibility and higher pressure ratings but can suffer early fatigue in dynamic applications where constant movement occurs. Consequently, metal hoses are typically used in static, high-pressure/temperature applications where permeation must be minimized.

Fluoropolymer Hoses (PTFE): Often employed in applications where chemical compatibility is crucial, PTFE hoses have smooth cores and are highly flexible. However, they can experience permeation in gas applications, especially with small molecules like hydrogen and helium. Gas molecules can migrate into the lattice structure of the fluoropolymer and eventually leak out.

Rubber and Thermoplastic Hoses: These hoses also feature smooth cores and are often chosen for specific applications, such as hydraulic systems (thermoplastic) or lower-criticality applications (rubber). Each core material has its strengths and weaknesses regarding permeation resistance.

Static Dissipation

A critical aspect often overlooked in hose selection is how the hose manages static dissipation. As gases or liquids flow through the hose, friction can cause a build-up of electrons on the inner core wall. In non-conductive materials (PTFE, Rubber, Thermoplastic), this charge accumulates until it jumps from the inner wall to the outer metal braid, creating a pinhole in the core tube and resulting in small leaks. When specifying a hose for applications where static dissipation is a concern, consider a metal core or a PTFE hose with a carbon-infused core. This infused core allows the static charge to travel slowly and in a controlled manner, preventing potentially damaging discharges.

Flexibility

Since hoses are often used in dynamic applications, flexibility is a critical characteristic to consider. Most hose vendors provide the minimum centerline bend radius, which is the point at which excessive bending can significantly reduce the hose's expected lifespan. Additionally, manufacturers typically publish a recommended minimum straight length before any bends occur after the end connection. This precaution prevents bending or kinking at the collar, extending the overall service life.

Insulation

Due to their typical placement in the field, hoses can pose significant safety risks for burns in hot services. Like other pipes or tubes, hoses can be insulated. Insulation protects operators from burns and can also insulate the process, resulting in lower heat losses.

Insulation offers some protection for the outer hose braid as well. A thermosleeve or spiral guard can shield the hose from abrasion as it moves and comes into contact with other surfaces where insulation may not be necessary. Additionally, an armor guard can further protect the hose from damage.

Our Factory

SHANDONG DANFLEX HOSE CO.,LTD. was founded in 2 0 0 9, located in Ningjin county, Dezhou city ,Shandong province, China.Specializing in the production of thermoplastic ultra high pressure hose and hydraulic hose with high tensile synthetic fiber or steel wire reinforcement for a working pressure range of 2 0 0 to 4 0 0 0 bar and inner diameters ranging from 3 to 2 5 mm.

FAQ

Hot Tags: ptfe hose, China ptfe hose manufacturers, suppliers, factory, SAE 100 R7 Hose, thermoplastic hose, grease hose, SAE 100 R8 Thermoplastic Hydraulic Hose, UHP Series Ultra High Pressure Flexible Hose, Ultra High Pressure Water Blast Hose